FBD Machine Manufacturer

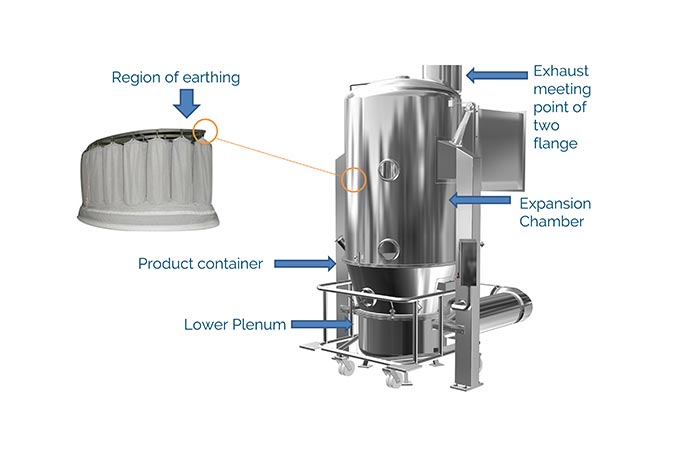

Fluid Bed Dryer offers a lucid solution to drying of wet granules, crystalline or coarse materials. It utilizes the principle of passing the hot air at a high velocity through the bed of the material to be dried, thus causing it to fluidize.

The blower situated on the exhaust side of the dryer operates no negative pressure principle, which creates the induced draught and sucks in the fresh air into the dryer. A stream of hot filtered air is introduced from the bottom of product container containing the wet material. This container is provided with the air distribution plate and Dutch sieve. The air stream is passed through the bed of the material and fluidizes the product particles by creating the turbulence in the product container. Due to fluidization each particle gets surrounded by hot air, which leads quick & uniform heating and drying. Filter bags provided at the top prevent escaping of particles from the machine.

Process of FBD Machine / Fluid Bed Dryer

The atmospheric air is sucked in the dryer through 5/10 micron filter by an efficient dynamically balanced fan driven by an electric motor. The clean air then passes over the electric heaters steam or oil radiator provided with temperature controller. The hot air passes through the product and fluidisation dries the product. Dryer is provided with dehumidifier (Chilled water system) at the inlet of the dryer so as to dry the product at low temperature under fluidized condition. The blower speed is controlled by A. C. frequency drive so as to control the fluidisation avoiding choking of the filter bag. A raking system provided to avoid lump formation in the container to achieve uniform fluidisation & uniform drying. A model with complete automation and PLC, automatic bag shaking and with mimic is also offered. Gaurav Engineering is manufacturer, supplier and exporter of fluid bed dryers according to ISI guidelines and user’s requirements since 2014 from Haryana to India and all over the world.

Industry We Serve

Chemical Industry Equipment Herbal Industry Equipment

Pesticides & Insecticides Industry Equipment

Food Processing Industry Equipment

Paint Manufacturing Industry Equipment

Phenol Formaldehyde Resin Industry Equipments

Starch Industry Equipments

Dyes Industry Equipments

Polymer Industry Equipments

Oil Plants Equipments

Phosphates Industry Equipments

Food and Edible Oil Industry Equipments

Detergents Industry Equipments