Reaction Vessel Manufacturer

We manufacture Chemical Reaction Mixing Vessel as per requirement of Customers. Design ensures that the Mixing of Chemical proceeds with the highest efficiency towards the desired output product, producing the highest yield of product as per requirement of customer. It may be provided with internal cooling coils if needed. Chemical reactor or reaction vessels are vessels design to facilitate chemical reaction among various raw chemicals, known as reactants. Reaction Vessels are also used for other processes such as solids dissolution, product mixing, distillation, crystallization, liquid/liquid extraction and polymerization. Reactors are also identified based on process for which it will be used (Such as blender or crystallizer). We are a Chemical Reactor Manufacturer for Pharmaceutical & Bulk Drugs, Chemical Industry, Herbal Industry, Pesticides & Insecticides Industry, Food Processing Industry, Paint Manufacturing Industry, Phenol Formaldehyde Resin Industry, Starch Industry, Dyes Industry, Polymer Industry, Oil Plants, Phosphates Industry, Food & Edible Oil Industry, Detergents Industry. We also know as Reactor, Jacketed Vessel, Limpet Vessel, Mixing Vessel, Formulation Vessel, Kettle, High Pressure Vessel, Homeginser and Agitated Vessel etc.

Process of Reaction Vessel:

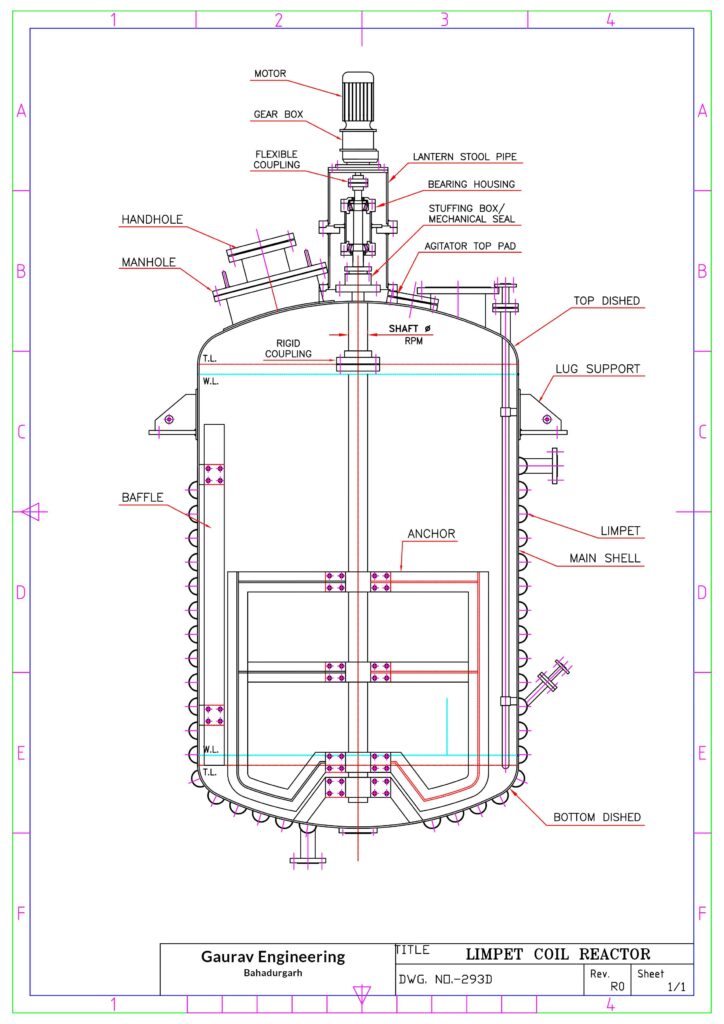

• Chemical Reactors or Jacketed Reaction Vessel consists of a cylindrical vertical shell with standard Torispherical dish on both ends. A Jacket is provided on the Outside of the shell for Heating & Cooling Stiffener Rings are provided on shell in between the shell and jacket to give uniform circulation of the heating or cooling media and to intensify the vessel. Ideally suitable for the heating below 150 Centigrade (302 Fahrenheit). Commonly used heat transfer media include water, steam, hot oil such as Thermion™, and Dowtherm A.

• Limpet Coil Reaction Vessel consists of a cylindrical vertical shell with standard Torispherical dish on both ends. Limpet Coil is half round Pipes welded on the outer surface of the shell and also on the bottom dish of the Reactor. Limpet coil is made of either Mild Steel or Stainless Steel. It is either Double end double start for both heating and cooling through limpet coil or Normal Single coil for either heating or cooling. Limpet Coil Welding is performed by using high grade By Flux Core filler wire depending on MOC of the Limpet Coil to withstand design pressure.

• Baffles are also provided inside the shell as per the requirement.

• Agitator assembly mounted on the Top dish of Reaction Vessel consists of Shaft supported by Lantern Assembly on the Top End containing Bearing Housing with Tapered roller bearing to withstand impact load and vibratory load ensuring smooth rotation of the Shaft.

• Shaft Can fitted with different types Of Agitator Such as Single Anchor, Double Anchor, Turbine & Propeller types.

Benefits of using Gaurav Engineering Reaction Vessel

• This Industrial Reaction Vessels are Design as per ASME Standard & Design of Reaction Vessels are very simple shape & scientifically.

• Design & Mfg with stainless steel Grade SS316L ,SS304L,IS 2062 (Raw material sourced from Tata, Jindal, Essar, Thyseen-Krupp, Arcelor- Mittal)

• Wide range of volumes from 500ltr to 50,000ltr.

• Ability to work under pressure and vacuum.

• Agitator/Stirring mechanism in accordance with the application of the reactor, viscosity and density of the product.

• We follow International quality standards in order to meet quality standards.

• Easy maintenance and robust quality therefore more demand able in market.

• These Industrial Reaction Vessels can be customized as per client’s requirements and Registered with leading consultants and third party inspection agency.

• Reliable After sales support and on time delivery.

Industry We Serve

Chemical Industry Equipment Herbal Industry Equipment

Pesticides & Insecticides Industry Equipment

Food Processing Industry Equipment

Paint Manufacturing Industry Equipment

Phenol Formaldehyde Resin Industry Equipments

Starch Industry Equipments

Dyes Industry Equipments

Polymer Industry Equipments

Oil Plants Equipments

Phosphates Industry Equipments

Food and Edible Oil Industry Equipments

Detergents Industry Equipments