Dyno Mill Or Bead Mill Manufacturer

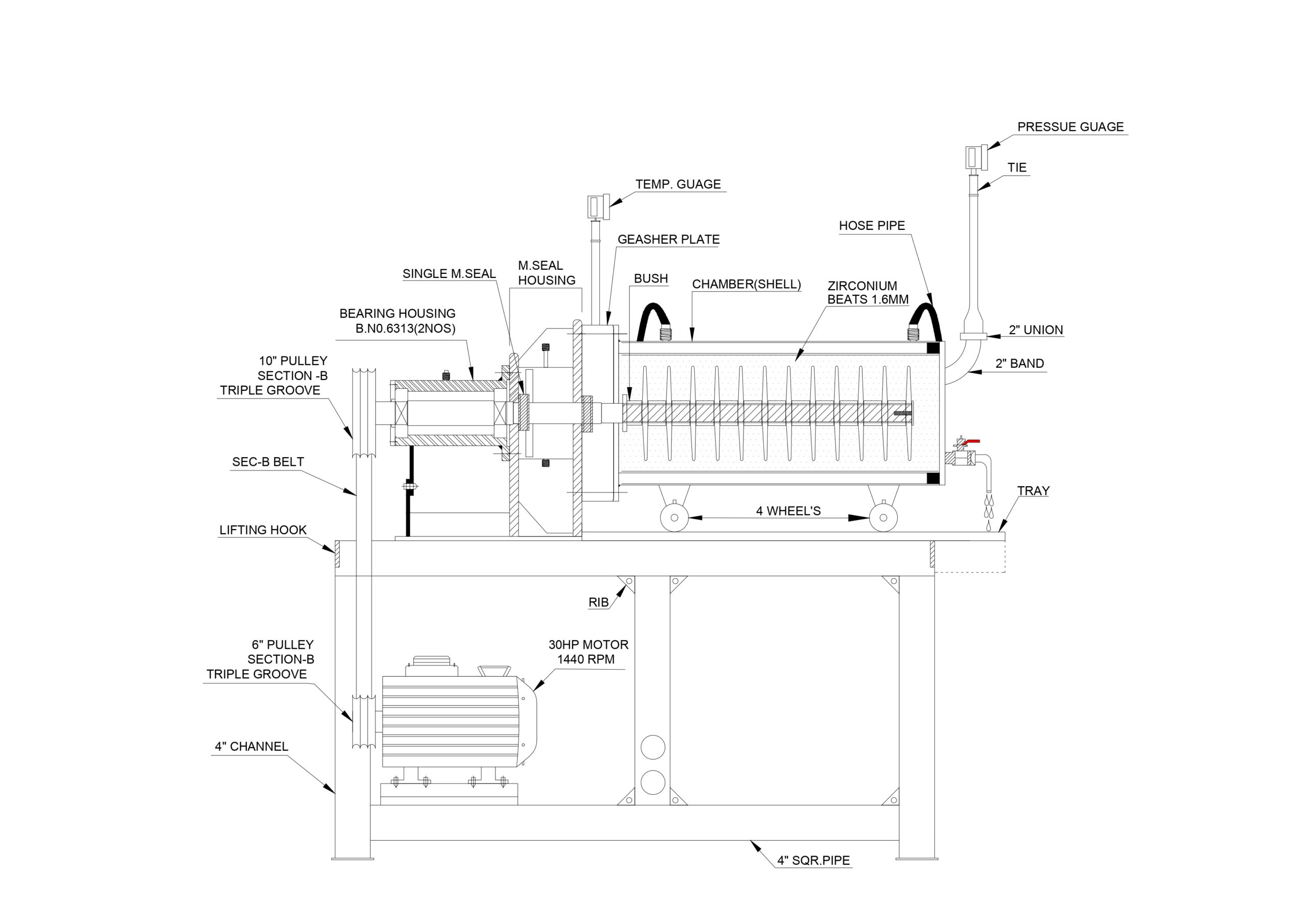

Dyno-Mill is an agitator bead mill with horizontal grinding container for dispersion and finest wet grinding in a completely enclosed system. The Dyno-Mill is suitable for all kinds of products from low to highly viscous pump able products. Specially designed agitator discs, mounted symmetrically on a shaft, transfer the energy required for dispersion and wet grinding to the spherical grinding beads. An external pump feeds the product into the mill.

Advantages of Gaurav Engineering Dyno Mill

We are Experienced Manufacturer of Dyno Mill for many prestigious companies & plants. Below are advantages of Gaurav Engineering Dyno Mill:-

1. Completely enclosed system

2. Highest efficiency

3. Easy operation and easy-to-service

4. Optimal geometry of grinding container and agitator discs

5. The appropriate mill size for every application

6. Different materials available for wear parts in contact with the product Fields of application

7. The blending technology is widely used in industries such as pharmaceutical industries, food processing, animal feed processing, chemical, fertilizers, cosmetics, pigments, and also insecticides manufacturing. The vertical blender mixer is also important in the process of distribution of liquids and pasty products in micro dosages on to carriers.

Process of Dyno Mill

Range

DYNO-Mills are available in different designs and sizes, from small laboratory models up to large mills for production plants, offering the optimal size for every application the mill equipment, materials, and grinding bead separation system can be adapted to the individual needs for each application.

Modular construction

All machine parts in contact with the product and subject to wear are easily replaceable and available in different materials. Modular construction allows easy conversion of mills already in operation.

Grinding containers

The slim construction of the grinding container guarantees a narrow residence time distribution. The high cooling efficiency attained by the spiral flow of the cooling water in the outer jacket allows the processing of highly viscous temperature-sensitive products.

Materials

The materials used depend on the size of the mill and the intended application. Wear parts can be made of alloyed stainless steel, chrome-plated stainless steel, tungsten carbide or synthetic materials.

For contamination-free dispersion and grinding mills up to 60 liters can be delivered with wear parts of high quality sintered materials or ceramic.

Grinding beads

Depending on the application and mill size, grinding beads of glass, ceramic, or steel from 0,15 mm — 3,0 mm are used. The grinding result is influenced directly by the size and type of the grinding beads.

Separation of the grinding beads

The grinding beads are retained in the mill by means of a dynamic gap separator or a special slot screen. The separation system used depends on the product being milled and the mill type.

Agitator discs

The agitator discs transfer the energy requires for dispersion and wet grinding to the grinding beads. The shape and arrangement of the discs guarantee optimal energy input and even distribution of the grinding beads in the grinding container.

Electrical control

Switches for local control of motor starters and instruments for monitoring the operating conditions are mounted on the mill; Safety limits on the mill are preset according to application.

Industry We Serve

Chemical Industry Equipment Herbal Industry Equipment

Pesticides & Insecticides Industry Equipment

Food Processing Industry Equipment

Paint Manufacturing Industry Equipment

Phenol Formaldehyde Resin Industry Equipments

Starch Industry Equipments

Dyes Industry Equipments

Polymer Industry Equipments

Oil Plants Equipments

Phosphates Industry Equipments

Food and Edible Oil Industry Equipments

Detergents Industry Equipments